Products

Constant torque friction hinges used in vehicle seat headrest TRD-TF15

Constant torque friction hinges are widely used in car seat headrests, providing passengers with a smooth and adjustable support system. These hinges maintain a consistent torque throughout the entire range of motion, allowing easy adjustment of the headrest to different positions while ensuring it stays securely in place.

In car seat headrests, constant torque friction hinges enable passengers to personalize their comfort by adjusting the height and angle of the headrest. This functionality is crucial for proper head and neck support, whether during relaxed driving or accommodating passengers of varying heights. By providing a safe, comfortable, and ergonomic seating experience, these hinges are essential components of car seat headrests.

Furthermore, constant torque friction hinges find applications beyond car seat headrests. They are commonly used in office chair headrests, adjustable sofa headrests, bed headrests, and even medical bed chairs. This versatile hinge allows for flexible adjustment in various seating and headrest products, enhancing overall comfort and support.

To summarize, constant torque friction hinges are not limited to car seat headrests alone. Their ability to provide adjustable angles and positions makes them invaluable in a wide range of seating and headrest applications, ensuring optimal comfort for users.

Constant torque friction hinges can be used in various types of chair headrests to provide adjustable and secure support. Some examples of chairs where these hinges can be applied include:

1.Office Chairs: Constant torque friction hinges are commonly used in office chairs with adjustable headrests. They allow users to customize the height and angle of the headrest to achieve optimal comfort during long hours of work.

2.Recliners: Reclining chairs, including lounge chairs and home theater seating, can benefit from constant torque friction hinges in their headrests. These hinges enable users to adjust the headrest to their preferred position, allowing for comfortable relaxation.

3.Dental Chairs: Dental chairs require adjustable headrests to accommodate patients of different sizes and maintain proper head and neck alignment during dental procedures. Constant torque friction hinges ensure secure and precise positioning of the headrest for patient comfort.

4.Salon Chairs: Salon chairs, used in hairstyling and beauty salons, often incorporate adjustable headrests. Constant torque friction hinges assist in providing a customized and comfortable experience for clients during salon services.

5.Medical Chairs: Medical chairs, such as treatment chairs and examination chairs, can employ constant torque friction hinges in their headrests. These hinges enable healthcare professionals to position the headrest accurately for patient examinations or treatments.

6.Massage Chairs: Constant torque friction hinges can enhance the adjustability of headrests in massage chairs, allowing users to customize the position and angle to meet their relaxation needs.

The versatility of constant torque friction hinges makes them suitable for various chair types, ensuring adjustable and secure headrest support across different settings and applications.

Friction damper TRD-TF15

|

Model |

Torque |

|

TRD-TF15-502 |

0.5Nm |

|

TRD-TF15-103 |

1.0Nm |

|

TRD-TF15-153 |

1.5Nm |

|

TRD-TF15-203 |

2.0Nm |

Tolerance:+/-30%

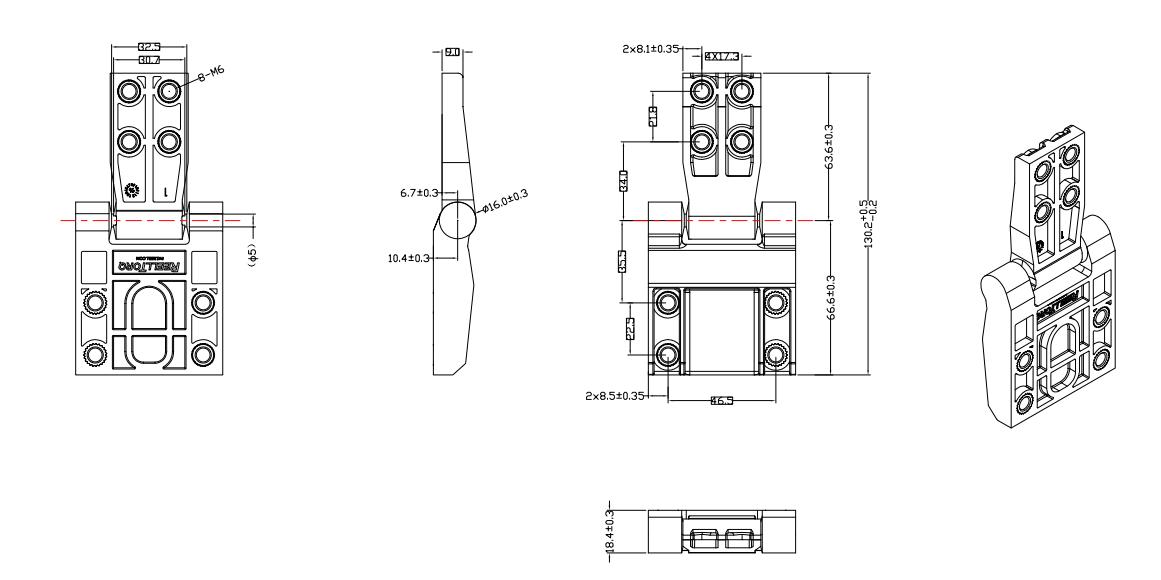

Size

Important Notes

1. During hinge assembly, ensure the blade surface is flush and the hinge orientation is within ±5° of reference A.

2. Hinge static torque range: 0.5-2.5Nm.

3. Total rotation stroke: 270°.

4. Material composition: Bracket and shaft end - 30% glass-filled nylon (black); Shaft and reed - hardened steel.

5. Design hole reference: M6 or 1/4 button head screw or equivalent.