Damping is a force that opposes the motion of an object. It is often used to control the vibration of objects or to slow them down.

A rotary damper is a small device that slows down the movement of a rotating object by creating fluid resistance. It can be used to reduce noise, vibration, and wear in various products.

Torque is a rotational or twisting force. It represents the capability of a force to produce change in the rotational motion of the body. It is often measured in Newton-meters (N.m).

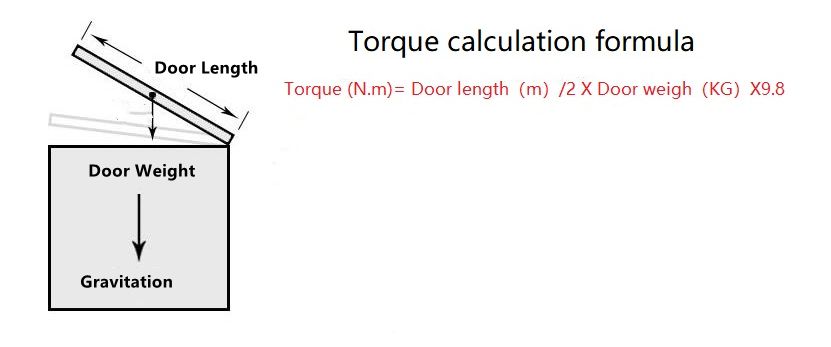

For example, in a soft-close door that uses a rotary damper, the only external force is the force of gravity. The torque of the damper is calculated as follows: Torque (N.m) = Door Length(m) /2x Force of gravity (KG)x9.8.Suitable torque for dampers in product design can make rotary dampers work more effectively.

The damping direction of a rotary damper is the direction in which the damper provides resistance to rotation. In most cases, the damping direction is one way, meaning that the damper only provides resistance to rotation in one direction. However, there are also two dampers that provide resistance to rotation in both directions.

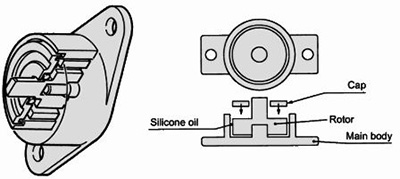

The damping direction of a rotary damper is determined by the design of the damper and the type of oil that is used in the damper. The oil in a rotary damper provides resistance to rotation by creating a viscous drag force. The direction of the viscous drag force depends on the direction of the relative motion between the oil and the moving parts of the damper.

In most cases, the damping direction of a rotary damper is chosen to match the direction of the expected forces on the damper. For example, if the damper is used to control the motion of a door, the damping direction would be chosen to match the direction of the force that is applied to open the door.

Rotary dampers work by rotating around a single axis. The oil inside the damper produces a damping torque that opposes the motion of the moving parts. The size of the torque depends on the oil viscosity, the distance between the moving parts, and their surface area. Rotary dampers are mechanical components that slow down movement through continuous rotation. This makes the use of the object on which they are installed more controlled and comfortable. The torque depends on the oil viscosity, the damper size, the robustness of the damper body, the rotation speed, and the temperature.

Rotary dampers can provide a number of benefits in a variety of applications. The specific benefits will depend on the specific application. These benefits including:

● Reduced noise and vibration: Rotary dampers can help to reduce noise and vibration by absorbing and dissipating energy. This can be beneficial in a variety of applications, such as in machinery, where noise and vibration can be a nuisance or even a safety hazard.

● Improved safety: Rotary dampers can help to improve safety by preventing equipment from moving unexpectedly. This can be beneficial in a variety of applications, such as in lifts, where unexpected movement could cause injury.

● Extended equipment life: Rotary dampers can help to extend the life of equipment by preventing damage from excessive vibration. This can be beneficial in a variety of applications, such as in machinery, where equipment failure can be costly.

● Improved comfort: Rotary dampers can help to improve comfort by reducing noise and vibration. This can be beneficial in a variety of applications, such as in vehicles, where noise and vibration can be a nuisance.

Rotary dampers are easy to integrate to a variety of industries to provide soft close or soft open movement of various objects. They are used to control open and close movement and provide silent smooth performance.

● Rotary dampers In automobile: seating, armrest, glove box, handles, fuel doors, glasses holders, cup holders, and EV chargers,sunroof,etc.

● Rotary dampers in home appliance and electronic appliances : refrigerators, washers/dryers , electrical cooker,ranges, hood, soda machines, dishwasher, and CD/DVD players, etc.

● Rotary dampers in sanitary industry: toilet seat and cover, or sanitary cabinet ,shower slide door, lid of dustbin etc.

● Rotary dampers in furniture: door or slide door of cabinet, lift table, tip-up seating, reel of medical beds, office hidden socket etc.

There are different types of rotary dampers available depending on their working angle, rotation direction, and structure. Toyou Industry provides rotary dampers,including: vane dampers, disk dampers, gear dampers and barrel dampers.

● Vane damper: This type has a finite working angle,120 degree at most and a one-way rotation,clockwise or anti-clockwise direction.

● Barrel damper: This type has an infinite working angle and a two-way rotation.

● Gear damper: This type has an infinite working angle and can be either one-way or two-way rotation. It has a gear-like rotor that creates resistance by meshing with the inner teeth of the body.

● Disk damper: This type has an infinite working angle and can be either one-way or two-way rotation. It has a flat disc-like rotor that creates resistance by rubbing against the inner wall of the body.

Apart from rotary damper, we have linear damper, soft close hinge ,friction damper and friction hinges for our choice.

There are a few key factors to consider when choosing a rotary damper for your application:

● Limited installation space: The limited installation space is the amount of space available for the damper to be installed.

● Working angle: The working angle is the maximum angle through which the damper can rotate. Make sure to choose a damper with a working angle that is greater than or equal to the maximum angle of rotation required in your application.

● Rotation direction: Rotary dampers can be either one-way or two-way. One-way dampers only allow rotation in one direction, while two-way dampers allow rotation in both directions. Choose the rotation direction that is appropriate for your application.

● Structure: The type of structure will affect the performance and characteristics of the damper. Choose the structure that is best suited for your application.

● Torque: The torque is the force that the damper exerts to resist rotation. Make sure to choose a damper with a torque that is equal to the torque required in your application.

● Temperature: Make sure to choose a damper that can operate at the temperature required in your application.

● Cost: The cost of rotary dampers can vary depending on the type, size, and other factors. Choose a damper that fits your budget.

The maximum torque of a rotary damper depends on its type and model. We provide our rotary dampers with torque requirements ranging from 0.15 N.cm to 14 N.m. Here are the different types of rotary dampers and their specifications:

● Rotary dampers can be installed in limited spaces with relevant torque requirements. The torque range is 0.15 N.cm to 14 N.m.

● Vane dampers are available in sizes from Ø6mmx30mm to Ø23mmx49mm, with different structures. The torque range is 1 N·M to 4 N·M.

● Disk dampers are available in sizes from disk diameter 47mm to disk diameter 70mm, with heights from 10.3mm to 11.3mm. The torque range is 1 N.m to 14 N.m.

● Big gear dampers include TRD-C2 and TRD-D2. The torque range is 1 N.cm to 25 N.cm.

TRD-C2 is available in sizes from outer diameter (including fixed position) 27.5mmx14mm.

TRD-D2 is available in sizes from outer diameter (including fixed position) Ø50mmx 19mm.

● Small gear dampers have a torque range of 0.15 N.cm to 1.5 N.cm.

● Barrel dampers are available in sizes around Ø12mmx12.5mm to Ø30x 28,3 mm. The item size varies depending on its design, torque requirement, and damping direction. The torque range is 5 N.CM to 20 N.CM.

The maximum rotation angle of a rotary damper depends on its type and model.

We have 4 types of rotary dampers - vane dampers,disk dampers,gear dampers and barrels damper.

For vane dampers-The maximum rotation angle of vane damper is 120 degree at the most.

For disk dampers and gear dampers - The maximum rotation angle of disk dampers and gear dampers are without limitation rotation angle, 360 degree free rotation.

For barrel dampers- The maximum rotation angle is only two-way, almost 360 degree.

The minimum and the the maximum operating temperature of a rotary damper depends on its type and model. We offer rotary dampers for the operating temperature from -40°C to +60°C .

The lifetime of a rotary damper depends on its type and model as well as how it is used. Our rotary damper can operate at least 50000 cycles without oil leakage.

It depends on the rotary dampers' type and model. We have 4 types of rotary dampers - vane dampers,disk dampers,gear dampers and barrels damper.

● For vane dampers- they can rotate in one way, either clockwise or anti-clockwise and the limtation of rotation angel is 110°

● For disk dampers and gear dampers- they can rotate both in one way or two way.

● For barrel dampers-they can rotation in two way.

Rotary dampers are designed to work in a wide range of environments. They can be used in high temperature and high humidity environments as well as in corrosive environments. However, it is important to choose the right type of rotary damper for the specific environment it will be used in.

Yes. We offer customized rotary damper. both ODM and OEM for rotary dampers are acceptable. We have 5 professional R& D team member,we can make a new tooling of rotary damper as per Auto cad drawing.

Please contact us for specification information.

Before installation rotary dampers, you need to obey the following rules:

● Check for compatibility with the rotary damper and its application.

● Do not use the damper outside of its specifications.

● Do not throw rotary dampers into fires as there is a danger of burning and explosion.

● Do not use if the maximum operating torque is exceeded.

● Check if the rotary damper is working properly by rotating it and observing if it moves smoothly and consistently.You can also test the torque of your rotary damper using a torque testing machine.

● If you have a specific application for your rotary damper, you can test it in that application to see if it works as intended.

We offer 1-3 free samples to business clients. The client is responsible for the international courier expense. If you do not have an international courier account No., please pay us the international courier expense and we will arrange the samples to be sent to you within 7 working days of receiving payment.

Inner carton with poly box or inner box. Outer carton with brown cartons. Some even with pallets.

Generally, we accept payment by West Union, paypal and T/T.

Our lead time for rotary dampers is generally 2-4 weeks. It depends on the real production status.

The length of time that rotary dampers can be kept in stock depends on the quality and structure of the rotary manufacturer. For Toyou Industry, our rotary dampers can be stocked for at least five years based on the tightness seal of our rotary damper and silicone oil.