Rotary dampers, also known as rotary or viscous dampers, are essential mechanical devices used to control the motion and speed of rotating objects. They provide smooth and controlled motion by dissipating kinetic energy, preventing sudden or jerky movements. In this comprehensive guide, we will explore the fundamental principles, applications, benefits, and design considerations of rotary dampers.

Section 1: Principles of Rotary Dampers

Rotary dampers work on the principle of fluid resistance or viscosity. Inside the damper, there is a well-contained fluid, often silicone-based, that flows through tiny orifices or through a precise gap between rotating and stationary parts. As the rotor rotates, the fluid is forced to pass through these restricted flow paths, creating resistance that slows down the motion and absorbs energy, thereby dampening the movement.

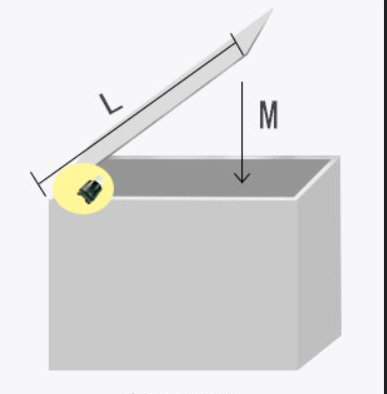

Rotary Dampers cannot work without external forces, such as gravity or other external forces. From the most basic structure of the damper, the Rotary Damper consists of the main body, the rotor, the closing’s cover and the internal viscous oil. However, when the damper moves under the action of external force, its rotor acts as a resistance (torque force) because the damper seals the internal sticky oil to prevent its movement. The sealing effect, viscous oil viscosity, and internal mechanical structure of the Rotary Damper determine its damper performance life and torsional stability.

Section 2: Applications of Rotary Dampers

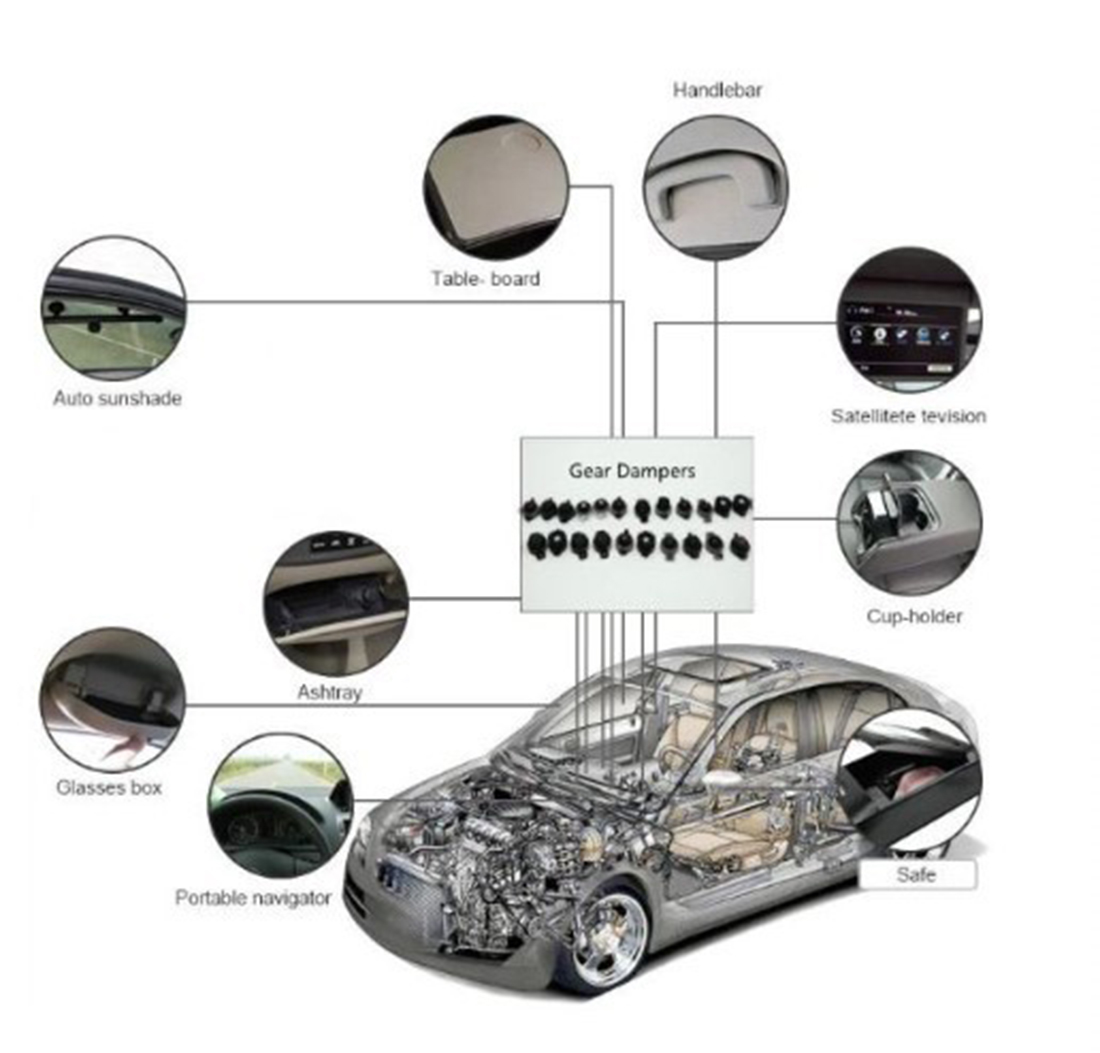

Rotary dampers find application in various industries. One of the most common uses is in the automotive sector, where they are utilized in vehicle glove box lids, center console compartments, and sunglass holders. They provide smooth opening and closing actions, preventing abrupt movements that can potentially damage the components.

In the furniture industry, rotary dampers are employed in cabinet doors, drawer slides, and toilet seat hinges. They ensure controlled and quiet movements, preventing slamming or accidental impacts. Other industries that benefit from rotary dampers include electronics, medical equipment, aerospace, and household appliances.

In the home application industry, rotary Dampers are used on the covers or doors of various consumer electrical household appliances, making the products safer, not easy to pinch hands, and also making electrical products safer and power-saving. Rotary Damper is applied to ploading washing machine. When the cover is closed, the washing machine cover has a built-in Rotary Damper. When the cover is closed, it is slowly and gently closed, so that the washing machine cover will not emit a huge noise when it is closed. Using its functions such as smooth motion control and soft closing, Rotary Dampers can also be applied to the cover of rice cooker, dryer, ice maker, freezer, coffee machine cover, soda maker, sandwich Makers and Grill, and so on.

Section 3: Benefits of Rotary Dampers

Rotary dampers offer several benefits, making them a preferred choice in various applications. Firstly, they enhance safety by preventing sudden movements or uncontrolled motions that can cause injuries or damage. Whether it’s a car compartment closing softly or a drawer sliding smoothly, rotary dampers ensure user comfort and convenience.

Additionally, rotary dampers improve product durability and longevity by reducing stress, vibrations, and impact forces. By absorbing and dissipating energy, they protect delicate components and mechanisms from excessive wear and tear. This results in increased product lifespan, reducing maintenance and replacement costs.

Furthermore, rotary dampers provide a premium feel and enhanced user experience by offering precise and consistent motion control. Whether it’s the soft closing of a toilet seat or the controlled opening of a laptop hinge, the smooth and reliable movement achieved through rotary dampers imparts a sense of quality and refinement.

Section 4: Design Considerations for Rotary Dampers

When designing with rotary dampers, several factors need to be taken into consideration. Firstly, the viscosity of the damper fluid is critical, as it determines the level of damping force provided. Choosing the right viscosity ensures optimal performance and compatibility with the intended application.

The size and form factor of the rotary damper are also vital design considerations. They need to be compact, lightweight, and fit within the available space. Additionally, the materials used for construction must be durable, corrosion-resistant, and suitable for the operating conditions.

Another crucial aspect is the adjustment mechanism. Some rotary dampers offer adjustability, allowing users to fine-tune the damping force according to their specific requirements. This flexibility can be advantageous in applications where the load or operating conditions may change.

In conclusion, rotary dampers play an indispensable role in motion control, providing smooth, controlled, and safe movement in various industries. Their applications are vast, ranging from automotive and furniture to electronics and aerospace. Understanding the principles, benefits, and design considerations of rotary dampers can empower engineers to utilize them effectively in their designs, enhancing product performance and user satisfaction.

Post time: Nov-29-2023