Products

Rotary Damper Metal Disk Rotation Dashpot TRD-70A 360 Degree Rotation Two Way

Disk Damper Specification

Disk Damper CAD Drawing

How to Use This Roatry Damper

1. Dampers function in both clockwise and counter-clockwise directions, generating torque accordingly.

2. It is important to note that the damper itself does not come with a bearing, so it is necessary to ensure that a separate bearing is attached to the shaft.

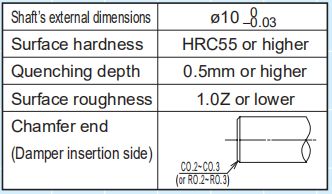

3. When creating a shaft for TRD-70A, please adhere to the recommended dimensions provided to prevent the shaft from slipping out of the damper.

4. To insert a shaft into TRD-70A, it is advised to spin the shaft in the idling direction of the one-way clutch rather than forcefully inserting it from the regular direction. This precaution helps to avoid damaging the one-way clutch mechanism.

5. When utilizing TRD-70A, it is crucial to insert a shaft with the specified angular dimensions into the damper's shaft opening. A wobbling shaft and damper shaft may impede proper deceleration of the lid during closing. Please refer to the accompanying diagrams on the right for the recommended shaft dimensions for the damper.

6. Additionally, a damper shaft that connects to a part with a slotted groove is also available. This slotted groove type is highly suitable for applications involving spiral springs, offering excellent functionality and compatibility.

Damper Characteristics

1. Speed characteristics

The torque of a disk damper is subject to variation based on rotation speed. Generally, as depicted in the accompanying graph, torque increases with higher rotation speeds and decreases with lower rotation speeds. This catalogue specifically showcases the torque values at a rotation speed of 20rpm. In the case of a closing lid, the initial stages of lid closure involve slower rotation speeds, resulting in the generation of torque that may be lower than the rated torque.

2. Temperature characteristics

The torque of the damper, indicated by the rated torque in this catalogue, shows sensitivity to changes in ambient temperature. With increasing temperature, the torque decreases, while decreasing temperature leads to an increase in torque. This behavior is attributed to the viscosity changes in the silicone oil contained within the damper, which is influenced by temperature variations. The accompanying graph provides a visual representation of the temperature characteristics.

Application For Rotary Damper Shock Absorber

Rotary dampers are highly reliable components for seamless motion control, finding wide applications in various industries. These include toilet seat covers, furniture, household appliances, automotive, transportation interiors, and vending machines. Their ability to provide smooth and controlled closing movements adds value to these industries, ensuring enhanced user experience and convenience.